How to Exponentially Enhance Industrial Workforce Productivity with Augmented Reality?

The industrial sector is quickly integrating augmented reality (AR) to amplify workforce productivity across diverse operational environments dramatically. AR overlays context-specific digital information and virtual objects onto the physical realm in real time. This creates an interactive and assistive experience that industrial workers can leverage to perform duties rapidly, safely, and with optimal precision.

Recent projections indicate the global market for AR solutions in industrial settings will skyrocket to $23 billion by 2028 as adoption proliferates. The technology has progressed from novel pilot deployments to mission-critical applications spanning manufacturing, construction, energy, transportation, healthcare, and other verticals. As AR devices become more powerful, practical, and affordable, every industrial organization must actively evaluate implementation strategies.

This article will highlight typical applications where AR boosts productivity across major industry verticals. We will also overview key benefits that multiply workforce efficiency and effectiveness through AR’s immersive capabilities. Finally, we will outline best practices and recommendations for integrating AR technology successfully within industrial organizations.

Optimizing Manufacturing Workflows

Progressive manufacturers are tapping into AR’s capabilities to increase factory productivity, quality, and safety. Instead of referencing instruction manuals; workers can visualize step-by-step processes and animations directly overlaid in their field of view as they assemble parts, machinery, or electronics. This allows for rapid learning while reducing assembly errors that result from misinformation.

AR also facilitates remote expert collaboration, enabling offsite specialists to see the worker’s real-time perspective through smart glasses and provide live guidance to resolve issues. Additional applications include machine maintenance, robotic programming, design simulations, part inspections, and inventory picks. Aerospace leaders like Boeing have reported 25-30% improvements in production quality and accelerated training timeframes after rolling out AR platforms across factories.

Beyond the production floor, AR supports product designers by rendering 3D CAD models into physical workspaces during prototyping. It also assists logistics teams with optimizing warehouse layouts and identifying shipping bottlenecks through AR data visualizations. The diverse manufacturing applications prove AR’s versatility and value.

Reimagining Construction Jobsites

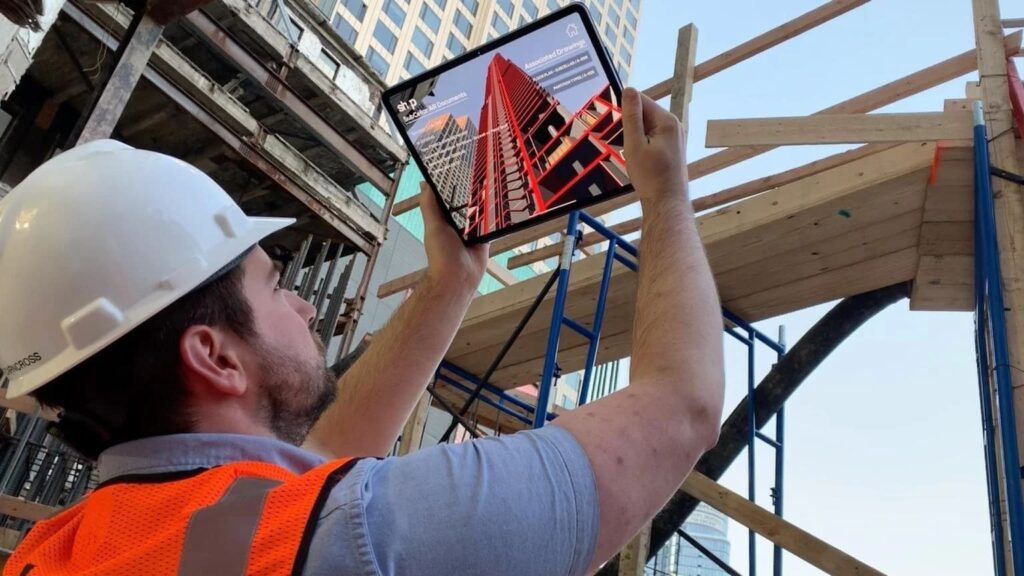

AR is revolutionizing productivity and work quality across the construction industry, from early architectural planning to ongoing site operations. During the design phase, architects and project stakeholders can instantly visualize and interact with a proposed building plan overlaid directly on the construction site through AR headsets. This immersive approach accelerates decision-making, reduces design defects, and creates a shared vision.

Once the building is underway, AR supports numerous aspects of the construction workflow. Heavy machine operators leverage AR when excavating, grading, and trenching, with dig sites and underground utility lines vividly overlaid on the equipment’s field of view. Construction teams use AR to visualize building information modeling (BIM) data on-site, ensuring the physical structure aligns properly with virtual 3D models.

AR also assists with critical inspections on completed buildings and infrastructure, providing annotatable overlays of wall assemblies, electrical/plumbing systems, and other structural components. This deeper visibility enables rapid identification of flaws. According to estimates, AR reduced inspection times by over 90% during the construction of SoFi Stadium in Los Angeles.

Enhancing Healthcare Delivery

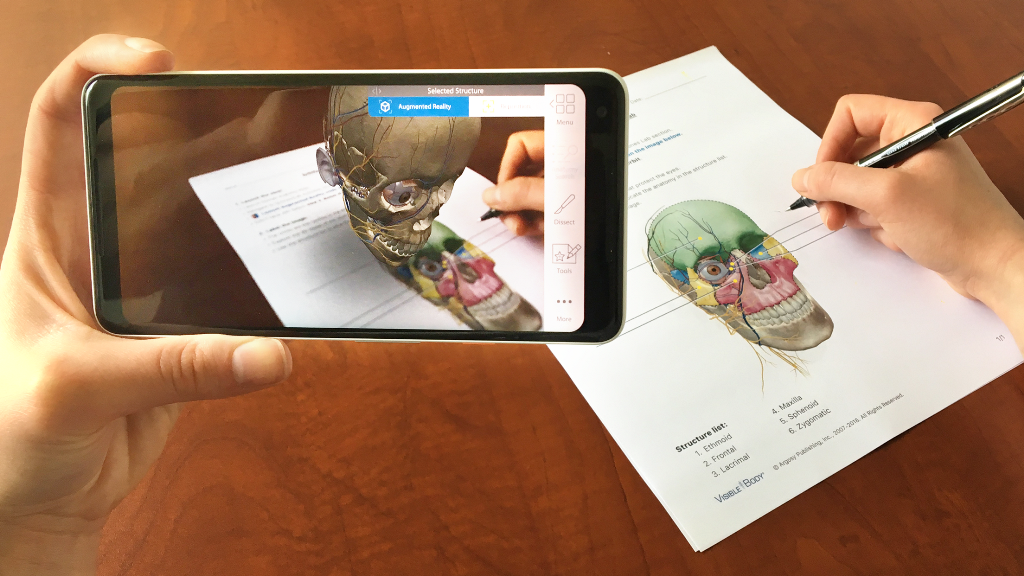

Healthcare institutions are tapping into AR’s powers to elevate patient care quality and outcomes through more effective workflows. Within surgical environments, AR allows doctors to reference 3D anatomical renderings specific to the patient overlaid directly on the body with pinpoint accuracy. Surgeons can also leverage AR headsets to view pre-op CT scans during complex procedures, ensuring real-time correlation between the patient’s internal anatomy and external physical presentation.

AR further enables surgeons to pull up relevant reference materials, best practice guides, and equipment checklists without breaking focus on the procedure. This heads-up insight improves accuracy while minimizing invasive surgical errors. Within intensive care units, nurses leverage AR when inserting IVs and catheters into patients with difficult-to-locate veins, visualizing below the skin in real-time.

For patient rehabilitation, physical therapists use AR to demonstrate ideal movements and exercises overlaid directly on patients’ bodies. The immersive perspective improves comprehension and outcomes. As healthcare grows more complex, AR will become indispensable for optimizing workflows while preventing critical oversights.

Multiplying Performance Across Sectors

The spectrum of augmented reality use cases that can amplify workforce productivity extends across countless industries. Within warehousing and logistics, AR devices enable pickers to locate inventory efficiently within extensive facilities and confirm orders with greater accuracy. Field technicians leverage AR when conducting equipment inspections and repairs, tapping into remote guidance to resolve issues faster.

In aviation manufacturing, aerospace companies use AR solutions to provide mechanics with interactive instructions overlaid directly on challenging assemblies like jet engines and airframes. AR supplies ground crews with real-time visualizations of refueling procedures and pre-flight safety checks on the tarmac. Across transportation, AR transforms training and maintenance for trucking fleets, railways, and maritime shipping.

Public safety and security teams also increasingly rely on AR technology. Police and tactical units leverage AR displays to obtain real-time situational updates, including building schematics, suspect locations, and mission objectives when responding to active incidents. AR enhances comprehension and coordination while keeping the user’s field of vision unobstructed. The unique capabilities of AR add measurable value across countless enterprise environments.

Core Benefits Driving Productivity

While use cases may differ, AR consistently delivers key benefits that drive productivity, efficiency, and workplace improvements:

Immersive Perspective

Unlike manuals or 2D images, AR provides an immersive, first-person view that closely replicates real-world conditions. This allows workers to access assets and environments instantly.

Workflow Optimization

AR visually guides workers through step-by-step processes in the ideal sequence. This eliminates inefficiencies from wasted motions or incorrect work.

Enhanced Focus

By overlaying annotations directly in a worker’s line of sight, AR enables heads-up insight while keeping hands free to multitask.

Precision Improvements

AR magnifies minute components and clarifies spatial relationships that are difficult to discern. This boosts precision and work quality.

Reduced Risk

AR identifies hazards, provides reminders on protocols, and enables remote mentorship. This improves workplace safety across industrial sites.

Knowledge Capture

AR environments can record training data and best practices, which are then preserved for new hires. Institutional knowledge is retained.

Best Practices for Integrating AR Solutions

While AR adoption requires upfront planning and investment, the technology’s long-term advantages vastly outweigh the initial costs when implemented strategically. Here are the best practices to consider:

- Pinpoint specific pain points and productivity gaps where AR could enhance performance based on worker feedback. Every use case should be tied to tangible ROI.

- Start with small AR pilot projects focused on high-impact applications. Successful pilots lay the groundwork for widespread adoption.

- Evaluate the leading AR hardware options and choose enterprise-grade devices suited to your needs. Consumer AR products lack the power, durability, and software capabilities required in industrial settings.

- Make technology usability a priority and provide extensive training sessions for employees at all levels on utilizing AR devices and software. User acceptance is crucial.

- Develop KPIs and metrics aligned to business objectives, which will be used to gauge AR impact on factors like quality, output, and safety. Analyze data continually post-launch.

- For large organizations, phase rollouts gradually across sites or departments. Take learnings from initial implementations to refine future AR expansion.

Based on this input, solicit user feedback frequently and enhance AR solutions over time. View AR as an evolving platform requiring ongoing management.

Closing Thoughts

Industrial organizations that dismiss AR technology as novelty risk ceding significant competitive advantage to early adopters. However, haphazard implementation of AR without a strategic roadmap also leads to lackluster results and wasted resources.

The most successful organizations take an iterative approach, carefully evaluating AR’s capabilities, deploying targeted pilot projects, and then scaling the technology across departments to multiply workforce productivity at an enterprise level. When combined with change management and continuous enhancement, AR delivers transformative productivity gains across manufacturing, construction, healthcare, and other industrial sectors.

To further explore how your organization can harness the power of augmented reality, connect with the experts at TILTLABS. Our full-lifecycle AR solutions are designed to deliver rapid ROI by amplifying worker capabilities through immersive technologies. Let us guide you on your augmented reality journey.